Space Saver Omni-Grid®

Select another product option

Features

Specifications

Options

Downloads

Features

SPACE SAVER OMNI-GRID® 100

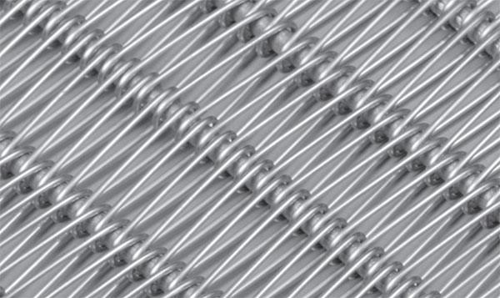

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

SPIRAL

LOTENSION

HYGENIC

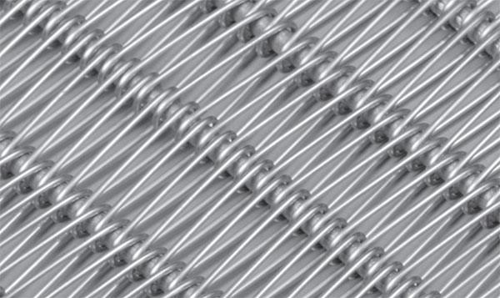

Proven Reliability

All Ashworth belts are rated for 100,000 cycles versus competition ratings of only 50,000 cycles

Reduced Wear

Patented “protrusion leg” design enables the belt to run smoother with less system wear

Increased Belt Life

Patented coining feature reduces run-in wear and increases belt life

DIRECTION

APPLICATIONS

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Specifications

Technical Specifications

Select another product option

| Technical Specifications | Units | Space Saver Omni-Grid® 100 |

|---|---|---|

| Turn Ratio | 2.2-2.5 | |

| Pitch | in. [mm] | 1.08 [27.4] |

| Available Widths: Curve/Spiral | in. [mm] | 12-36 [305-914] |

| Available Widths: Straight Run | in. [mm] | 12-36 [305-914] |

| Link Height | in. [mm] | 0.50 [12.7] |

| Rod Diameter/Material | in. [mm] | 0.192 [4.9] Metal |

| Conveying Surface | in. [mm] | Width -3.52 [-89.4] |

| Allowable Tension (Curve/Spiral) | lb. [kg] | 150 [68] at 100,000 cycles (when configured for maximum strength) |

| Allowable Tension (Straight Run) | lb. [kg] | 300 [136] at 100,000 cycles (when configured for maximum strength) |

| Turn Direction | Uni-directional (left or right-must specify direction) | |

| Mode of Turning | Outside edge expands in turn | |

| Method of Drive | Sprockets driven on links |

Available Sprocket Options

Sprocket Reference

Select another sprocket size

Select a product

| Nom. Size | Display | Teeth | Pitch Diameter in (mm) | Hub Diameter in (mm) | Bore Min in (mm) | Bore Max in (mm) |

|---|---|---|---|---|---|---|

| 6 | #6-19 T303 DT | 19 | 6.77 (171.86) | 6.03 (153.21) | 0.88 (22.22) | 4.8 (121.92) |

| 6 | #6-19 UHMW DT | 19 | 6.77 (171.86) | 6.03 (153.21) | 0.88 (22.22) | 4.67 (118.62) |

*Maximum bores provide adequate material thickness for standard keyway. Specify special sized to be used when necessary.

Material Reference

- Acetal - polyoxymethylene plastic

- Celcon - acetal copolymer

- CI - cast iron

- Hardened Steel

- Nylon

- T303 - stainless steel

- T316 - stainless steel

- UMHW - polyethylene plastic

Need more detailed information?

Need more detailed information?

Need more detailed information?

Belt Calculator

No Results

Base Belt Weight

Belt Pitch

Turn Ratio

Belt Strength

Min Filler Roll Diameter

Conveying Surface

Inside Conveying Surface

Outside Conveying Surface

Mesh Opening Size

Open Area Surface

Open Area Thru

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

Omni-Tough Mesh Overlay

- Stainless steel, spring wire, spiral overlay available in 16 and 17 wire gauges.

- 2-1/2 times stronger and more damage-resistant than conventional wire overlays.

- Provides a flatter surface than standard overlays.

- More resistant to product sticking in freezer application.

Designation

B/U X - Y - Z

- B/U = Balanced or Unilateral Weave

- X = Number of Loops/Foot of Width

- Y = Number of Spirals/Foot of Length

- Z = Wire Gauge of Overlay

Examples:

B30-16-16

U42-16-17

Need more detailed information?

Need more detailed information?

Need more detailed information?

Downloads

Downloads

Installation, Assembly & Maintenance Instructions

Conveyor System Review Form

Features

SPACE SAVER OMNI-GRID® 75

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

SPIRAL

LOTENSION

HYGENIC

Proven Reliability

All Ashworth belts are rated for 100,000 cycles versus competition ratings of only 50,000 cycles

Reduced Wear

Patented “protrusion leg” design enables the belt to run smoother with less system wear

Increased Belt Life

Patented coining feature reduces run-in wear and increases belt life

DIRECTION

APPLICATIONS

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Specifications

Technical Specifications

Select another product option

| Technical Specifications | Units | Space Saver Omni-Grid® 075 |

|---|---|---|

| Turn Ratio | 2.2-6.0 | |

| Pitch | in. [mm] | 0.75 [19.0] |

| Available Widths: Curve/Spiral | in. [mm] | 12-36 [305-914] |

| Available Widths: Straight Run | in. [mm] | 12-36 [305-914] |

| Link Height | in. [mm] | 0.44 [11.1] |

| Rod Diameter/Material | in. [mm] | 0.192 [4.9] Metal |

| Conveying Surface | in. [mm] | Width -3.43 [-87.0] |

| Allowable Tension (Curve/Spiral) | lb. [kg] | 150 [68] at 100,000 cycles (when configured for maximum strength) |

| Allowable Tension (Straight Run) | lb. [kg] | 300 [136] at 100,000 cycles (when configured for maximum strength) |

| Turn Direction | Uni-directional (left or right-must specify direction) | |

| Mode of Turning | Outside edge expands in turn | |

| Method of Drive | Sprockets driven on links |

Available Sprocket Options

Sprocket Reference

Select another sprocket size

Select a product

| Nom. Size | Display | Teeth | Pitch Diameter in (mm) | Hub Diameter in (mm) | Bore Min in (mm) | Bore Max in (mm) |

|---|---|---|---|---|---|---|

| 6 | #6-27 T303 DT FS | 27 | 6.42 (163.12) | 5.97 (151.61) | 0.5 (12.7) | 4.74 (120.4) |

| 6 | #6-27 UHMW DT FS | 27 | 6.42 (163.12) | 5.97 (151.61) | 0.5 (12.7) | 4.61 (117.09) |

*Maximum bores provide adequate material thickness for standard keyway. Specify special sized to be used when necessary.

Material Reference

- Acetal - polyoxymethylene plastic

- Celcon - acetal copolymer

- CI - cast iron

- Hardened Steel

- Nylon

- T303 - stainless steel

- T316 - stainless steel

- UMHW - polyethylene plastic

Need more detailed information?

Need more detailed information?

Need more detailed information?

Belt Calculator

No Results

Base Belt Weight

Belt Pitch

Turn Ratio

Belt Strength

Min Filler Roll Diameter

Conveying Surface

Inside Conveying Surface

Outside Conveying Surface

Mesh Opening Size

Open Area Surface

Open Area Thru

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

Omni-Tough Mesh Overlay

- Stainless steel, spring wire, spiral overlay available in 16 and 17 wire gauges.

- 2-1/2 times stronger and more damage-resistant than conventional wire overlays.

- Provides a flatter surface than standard overlays.

- More resistant to product sticking in freezer application.

Designation

B/U X - Y - Z

- B/U = Balanced or Unilateral Weave

- X = Number of Loops/Foot of Width

- Y = Number of Spirals/Foot of Length

- Z = Wire Gauge of Overlay

Examples:

B30-16-16

U42-16-17

Need more detailed information?

Need more detailed information?

Need more detailed information?

Downloads

Downloads

Installation, Assembly & Maintenance Instructions

Conveyor System Review Form