THE FUTURE WILL BE DIGITIZED!

- Real-time spiral performance data anytime, anywhere

- Continuous monitoring of spiral temperature, belt tension, cage power and motor power with expandability for 3 more sensors

- Features the industry’s first patented bottom bearing wear sensor

- Secure stand-alone monitoring, independent of plant’s network

- Access to multiple spirals and plant locations from one screen

- Easy-to-see user alerts and system feedback

SmartSpiral® Monitoring System

Features

Downloads

Features

SmartSpiral® Monitoring System

Real Time monitoring of multiple spirals at different locations - from anywhere

Real Time monitoring of multiple spirals at different locations - from anywhere

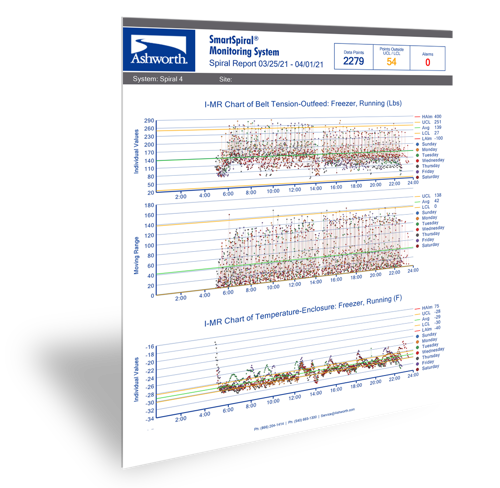

Performance amplified through live and historical data analysis to fine-tune your equipment and maximize productivity

Continuous monitoring of spiral temperature, belt tension, cage power and motor power with expandability for 3 more sensors

MULTIPLE SENSOR OPTIONS AND LOCATION POSSIBILITIES

Belt Tension

Bottom Bearing

Temperature

Cage Drive

Outfeed Drive

See it in action

Peak performance made possible through data and automation

SmartSpiral’s easy-to-use technology, can be accessed via computer, tablet, or a smartphone, simplifies your manufacturing processes, and makes production management easier.

Identify performance issues, prevent failures, and minimize downtime.

By alerting plant engineers and managers with notifications regarding potential system failures, SmartSpiral ensures peace-of-mind by predicting problems before they occur. Alarm notifications include identification of fault, the date and time that an issue was detected, and the location of the facility.

Now you can plan and prioritize your maintenance costs

Downtime in manufacturing wreaks havoc on production standards. It’s estimated that almost every factory experiences as much as a 20% loss due to downtime, adding up to thousands of dollars in revenue loss.

Secure stand-alone monitoring, independent of the plant’s network

Expert analysis, reporting and recommendations included.

Real-time monitoring and alerts available on any device.

See it in action

APPLICATIONS

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Downloads

Downloads