Modular Plastic Conveyor Belt with Maximum Open Area.

Prestoflex®

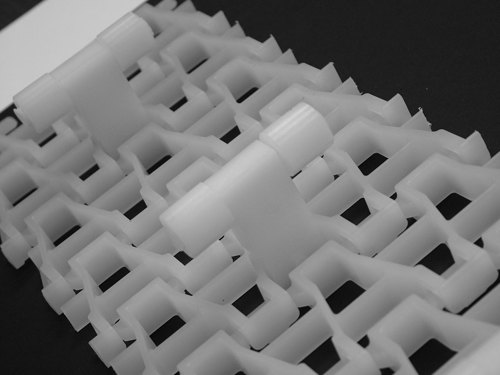

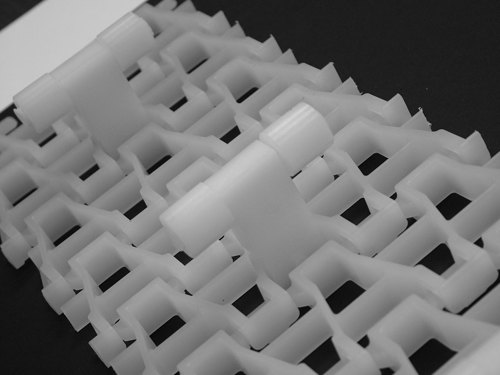

Prestoflex® modular plastic conveyor belting comes in two surface options. The open grid version provides maximum openness for air and water passage, making it ideal for washing applications. The closed oval version offers a smooth and flat surface with small oval perforations. Plastic sprockets are stocked in convenient sizes.

Prestoflex®

Select another product option

Features

Specifications

Options

Downloads

Features

EASY ASSEMBLY AND REPAIR WITH UNIQUE CONNECTOR-LESS CONSTRUCTION

Prestoflex® modular plastic conveyor belting has NO connectors, which makes it popular with maintenance mechanics. Prestoflex® plastic modules easily snap together for assembly and unsnap for replacement and repairs. A screwdriver is all that is needed to simply and quickly install modules and get your conveyor belt system up and running again.

WIDE RANGE OF APPLICATIONS

Prestoflex® conveyor belting will fit on many existing process conveyors presently using metal, plastic or rubber belting. Ashworth Product Engineers will carefully match your requirements with the belt's capabilities for maximum efficiency and belt life.

POSITIVE DRIVE FOR PRECISE CONVEYING

Prestoflex® conveyor belting is positively driven with matching sprockets. Machined Ultra High Molecular Weight Polyethylene or molded HDPE sprockets are available.

DIRECTION

STRAIGHT RUN

APPLICATIONS

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Specifications

Technical Specifications

Select another product option

| Technical Specifications | Units | Prestoflex OG |

|---|---|---|

| Pitch | in. [mm] | 2.0 [50.8] |

| Available Widths | in. [mm] | 6-96 [152-2438] |

| Thickness | in. [mm] | 0.62 [15.9] |

| Turn Capability | Straight run only | |

| Conveying Surface | Belt Width (Straight run only) | |

| Open Area | 55% | |

| Minimum Temperature | °F [°C] | 32 [0] Polypropylene |

| Maximum Temperature | °F [°C] | 212 [100] Polypropylene |

| Method of Drive | Positively driven with precision sprockets |

Available Sprocket Options

Sprocket Reference

Select another sprocket size

Select a product

| Nom. Size | Display | Teeth | Pitch Diameter in (mm) | Hub Diameter in (mm) | Bore Min in (mm) | Bore Max in (mm) |

|---|---|---|---|---|---|---|

| 4 | #4-6 UHMW | 6 | 3.43 (87.25) | 2.87 (72.9) | 0.74 (18.67) | 2 (50.8) |

| 4 | #4-6 UHMW | 6 | 3.81 (96.85) | 2.87 (72.9) | 0.99 (25.02) | 2 (50.8) |

| 6 | #6-10 UHMW | 10 | 6.47 (164.34) | 5.66 (143.76) | 1 (25.4) | 4.3 (109.22) |

| 6 | #6-10 UHMW | 10 | 6.47 (164.34) | 5.66 (143.76) | 1.44 (36.51) | 4.3 (109.22) |

| 6 | #6-10 UHMW | 10 | 6 (152.43) | 5.53 (140.46) | 0.99 (25.02) | 4.17 (105.92) |

| 6 | #6-10 UHMW | 10 | 6 (152.43) | 5.53 (140.46) | 1.5 (38.1) | 4.17 (105.92) |

| 8 | #8-13 UHMW | 13 | 8.36 (212.27) | 7.71 (195.94) | 0.99 (25.02) | 5.99 (152.15) |

| 10 | #10-17 UHMW | 17 | 10.88 (276.35) | 10.16 (258.06) | 0.99 (25.02) | 8.42 (213.87) |

| 12 | #12-20 UHMW | 20 | 12.78 (324.71) | 12 (304.8) | 1 (25.4) | 10.26 (260.6) |

| 12 | #12-20 UHMW | 20 | 12.78 (324.71) | 12 (304.8) | 1.5 (38.1) | 10.26 (260.6) |

| 12 | #12-20 UHMW Split | 20 | 12.78 (324.71) | 12 (304.8) | 1.57 (40) | 10.26 (260.6) |

UHMWPE material type components have a 150°F [66°C] maximum operating temperature.

*Maximum bores provide adequate material thickness for standard keyway. Specify special sized to be used when necessary.

Material Reference

- Acetal - polyoxymethylene plastic

- Celcon - acetal copolymer

- CI - cast iron

- Hardened Steel

- Nylon

- T303 - stainless steel

- T316 - stainless steel

- UMHW - polyethylene plastic

Belt Calculator

No Results

Base Belt Weight

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

UHMWPE Hangers

UHMWPE hanger brackets are available for use in can hold-down applications.

Open or Closed Grid

PrestoFlex® is available in either open grid or closed oval grid plastic components

Open Grid

Closed Grid

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Downloads

Downloads

Installation, Assembly & Maintenance Instructions

Other Files

Conveyor System Review Form

Features

EASY ASSEMBLY AND REPAIR WITH UNIQUE CONNECTOR-LESS CONSTRUCTION

Prestoflex® modular plastic conveyor belting has NO connectors, which makes it popular with maintenance mechanics. Prestoflex® plastic modules easily snap together for assembly and unsnap for replacement and repairs. A screwdriver is all that is needed to simply and quickly install modules and get your conveyor belt system up and running again.

WIDE RANGE OF APPLICATIONS

Prestoflex® conveyor belting will fit on many existing process conveyors presently using metal, plastic or rubber belting. Ashworth Product Engineers will carefully match your requirements with the belt's capabilities for maximum efficiency and belt life.

POSITIVE DRIVE FOR PRECISE CONVEYING

Prestoflex® conveyor belting is positively driven with matching sprockets. Machined Ultra High Molecular Weight Polyethylene or molded HDPE sprockets are available.

DIRECTION

STRAIGHT RUN

APPLICATIONS

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Specifications

Technical Specifications

Select another product option

| Technical Specifications | Units | Prestoflex COG |

|---|---|---|

| Pitch | in. [mm] | 2.0 [50.8] |

| Available Widths | in. [mm] | 6-96 [152-2438] |

| Thickness | in. [mm] | 0.62 [15.9] |

| Turn Capability | Straight run only | |

| Conveying Surface | Belt Width (Straight run only) | |

| Open Area | 35% | |

| Minimum Temperature | °F [°C] | 32 [0] Polypropylene |

| Maximum Temperature | °F [°C] | 212 [100] Polypropylene |

| Method of Drive | Positively driven with precision sprockets |

Available Sprocket Options

Sprocket Reference

Select another sprocket size

Select a product

| Nom. Size | Display | Teeth | Pitch Diameter in (mm) | Hub Diameter in (mm) | Bore Min in (mm) | Bore Max in (mm) |

|---|---|---|---|---|---|---|

| 4 | #4-6 UHMW | 6 | 3.43 (87.25) | 2.87 (72.9) | 0.74 (18.67) | 2 (50.8) |

| 4 | #4-6 UHMW | 6 | 3.81 (96.85) | 2.87 (72.9) | 0.99 (25.02) | 2 (50.8) |

| 6 | #6-10 UHMW | 10 | 6.47 (164.34) | 5.66 (143.76) | 1 (25.4) | 4.3 (109.22) |

| 6 | #6-10 UHMW | 10 | 6.47 (164.34) | 5.66 (143.76) | 1.44 (36.51) | 4.3 (109.22) |

| 6 | #6-10 UHMW | 10 | 6 (152.43) | 5.53 (140.46) | 0.99 (25.02) | 4.17 (105.92) |

| 6 | #6-10 UHMW | 10 | 6 (152.43) | 5.53 (140.46) | 1.5 (38.1) | 4.17 (105.92) |

| 8 | #8-13 UHMW | 13 | 8.36 (212.27) | 7.71 (195.94) | 0.99 (25.02) | 5.99 (152.15) |

| 10 | #10-17 UHMW | 17 | 10.88 (276.35) | 10.16 (258.06) | 0.99 (25.02) | 8.42 (213.87) |

| 12 | #12-20 UHMW | 20 | 12.78 (324.71) | 12 (304.8) | 1 (25.4) | 10.26 (260.6) |

| 12 | #12-20 UHMW | 20 | 12.78 (324.71) | 12 (304.8) | 1.5 (38.1) | 10.26 (260.6) |

| 12 | #12-20 UHMW Split | 20 | 12.78 (324.71) | 12 (304.8) | 1.57 (40) | 10.26 (260.6) |

Material Reference

- Acetal - polyoxymethylene plastic

- Celcon - acetal copolymer

- CI - cast iron

- Hardened Steel

- Nylon

- T303 - stainless steel

- T316 - stainless steel

- UMHW - polyethylene plastic

Belt Calculator

No Results

Base Belt Weight

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

UHMWPE Hangers

UHMWPE hanger brackets are available for use in can hold-down applications.

Open or Closed Grid

PrestoFlex® is available in either open grid or closed oval grid plastic components

Open Grid

Closed Grid

Does this meet your project needs?

Does this meet your project needs?

Does this meet your project needs?

Let’s get started!

Let’s get started!

Let’s get started!

Downloads

Downloads

Installation, Assembly & Maintenance Instructions

Other Files

Conveyor System Review Form